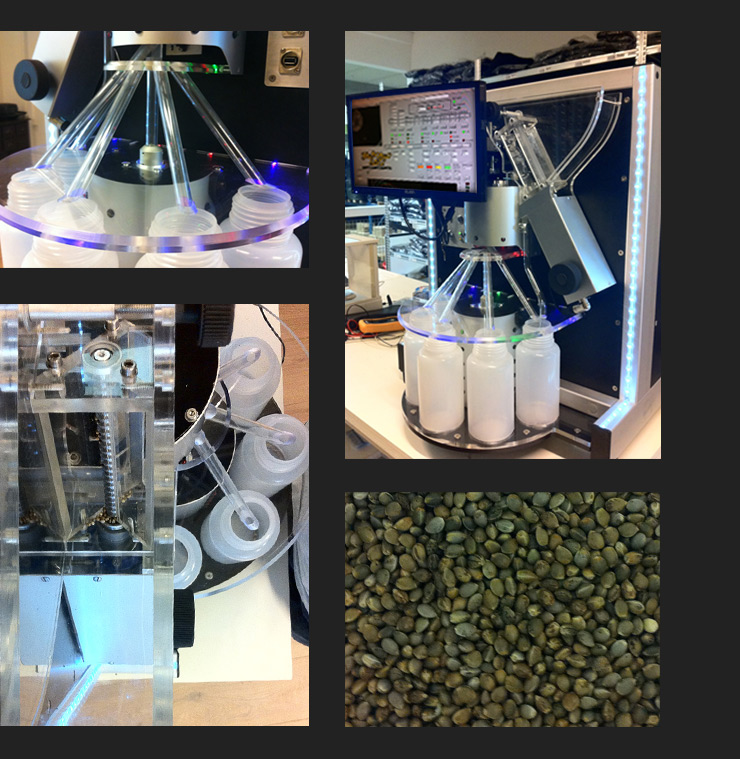

GREEN HOUSE SEED SELECTOR

Green House Seed Company is proud to be at the cutting edge of cannabis research, year after year. Starting in 2005 and 2006 with the first resin macro-photography, we developed a series of innovations that changed our industry. We were the first seed bank to extensively apply cannabinoid and terpens testing to all our strains, and we were the first to apply a color-coating over our seeds. Ever since we exist, we have been devoting a significant part of our profits to research and development to the benefit of our customers, as well as the cannabis industry as a whole.Now, after 3 years of development, we are ready to present our newest creation: the Green House Seed Selector, a new tool to select cannabis seeds that will change forever the way we work.Until today, selection of seeds could be done in many ways, but always with the use of manpower. The task of selecting seeds prior to packaging is very delicate, and only very experienced people can acquire the necessary sensitivity and eye for the detail. Selecting seeds one by one has always been, together with manicuring bud, one of most tedious jobs in the whole cannabis industry.Now we developed a standardized, scientific and efficient way of selecting cannabis seeds based on their germination potential, size and appearance.The Green House Seed Selector is designed to select seeds based on several parameters. The Selector is fed unselected seeds, (on average, a batch of unselected seeds contains between 10% and 20% of white, immature or underdeveloped seeds) and through the use of a percussion meter and a high-resolution camera the output is divided in 5 containers, containing batches of seeds divided based on their size, weight and look. Of the 5 containers, one is used to collect seeds that have to be processed again (the machine was unsure of the quality); one is used to collect immature seeds; and the remaining three containers collect the good seeds, dividing them in 3 different batches based on aspect, size, pattern.The first step is to lift seeds and drop each one on a percussion sensor, that determines the weight and density of the seed. Then a high definition camera measures the area and the volume of the seed, and takes several pictures to determine the color and the pattern on the seed shell.The selection process takes between 2 and 3 seconds per seed, allowing the selection of just over one pound of seeds per day (continuous 24hrs operation).The parameters for the selection are different for each strain, because the seeds are different in color, shape, size and density. So we developed individual settings for each single strain, that we can import into the machine at the beginning of each selection cycle. For each strains the machine can then select and divide seeds based on the packaging needs.The Green House Seed Selector combines mechanical and electronic elements and is controlled by a unique combination of a digital processor and a control and measurement unit specially developed for this machine. The software and algorithms are unique, and never before utilized in a machine.We introduced the Green House Seed Selector at the 2011 Spannabis Expo in Barcelona, where we demonstrated its use to the media, the industry operators and the general public. Now we use it to select seeds before they are packaged, to guarantee our customers that the product is the best quality the industry has to offer.And we are already working at making this prototype into a real product, one that one day will be the standard of the industry to certify viable, healthy cannabis seeds.